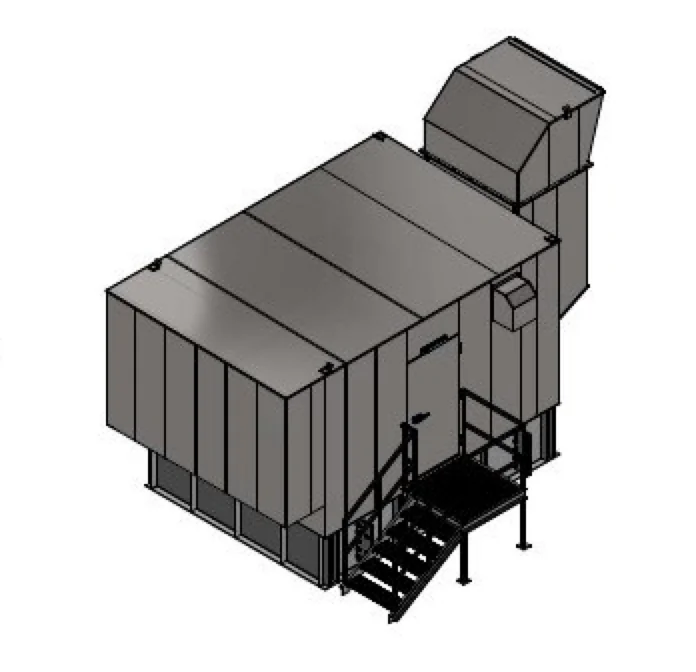

BC Hydro UPS & Diesel Genset Enclosure Structural Design

Client: Black Box Manufacturing Inc. (for BC Hydro through POMERLEAU)

Location: Langley Twp., BC

Structural FEA, detailed design, and full integrity analysis of UPS enclosure and Diesel Genset package enclosure, including seismic and lift design per IEEE 693-2018 and BC Hydro requirements.

Project Overview

This enclosure required structural integrity validation for multiple stringent load cases and practical detailing for fabrication and installation, including seismic, wind, lifting, and shipping considerations.

The enclosures served as protective housings for critical electrical equipment and diesel-generator package requiring tricky structural design that ensured equipment protection under various severe loading conditions. A critical aspect was their exposure to strong wind / storm on top of a hill plus earthquake, loads transferred through the fuel tank, and lifting system design for safe crane handling during installation.

Engineering Approach

IFEL performed comprehensive structural finite element analysis (FEA) for governing load cases and produced detailed calculation packages to support traceability and review. The analysis was conducted in accordance with IEEE 693-2018 (IEEE Recommended Practice for Seismic Design of Substations) and BC Hydro additional requirements including SP16 (DG AND UPS ENCLOSURES) and SP22 (SEISMIC REQUIREMENTS).

Finite element analysis was utilized to model both enclosure structures, including roof, wall, and floor sections. Load case analysis encompassed dead, live, snow, wind, seismic, and shipping loads per applicable standards. The design addressed unique challenges including exposure to strong wind and storm conditions on top of a hill, earthquake loads, loads transferred through the fuel tank, and lifting lug design for safe crane operations during installation.

- IEEE 693-2018 compliant seismic design and analysis

- BC Hydro SP16 and SP22 requirements compliance

- Dead, live, snow, wind, seismic, and shipping load checks

- Lift design considerations and lug sizing for crane operations

- Wind and storm load analysis for hilltop exposure

- Fuel tank load transfer analysis

- Documentation suitable for QA/QC and client turnover

Outcome

The client received a complete structural design and analysis package supporting fabrication and delivery to the end user. The comprehensive design package enabled successful fabrication, with all structural elements validated for the required load cases including seismic, wind, lifting, and shipping conditions. Both the UPS enclosure and Diesel Genset package enclosure were designed to meet all BC Hydro requirements and IEEE 693-2018 standards.

Day to Day Halal Market – Commercial Kitchen Design

Port Coquitlam, BC

Commercial kitchen engineering covering ventilation, fire protection, plumbing, and gas, delivered in phased execution.

Earls Spreader Model 807 RE Mainframe Weldment

Greater Vancouver Area, BC

Structural capacity review and finite element analysis supporting fabrication decisions for a 42LT rated load.

Vibration Problem-Solving - Digested Sludge Feed Piping System

LONA Wastewater Treatment Plant

Rapid problem-solving engineering to resolve severe commissioning vibration in a critical sludge feed piping system.

Ready to Work With Us?

Want a similar outcome on your project? Tell us your scope and constraints and we’ll propose a clear engineering plan.