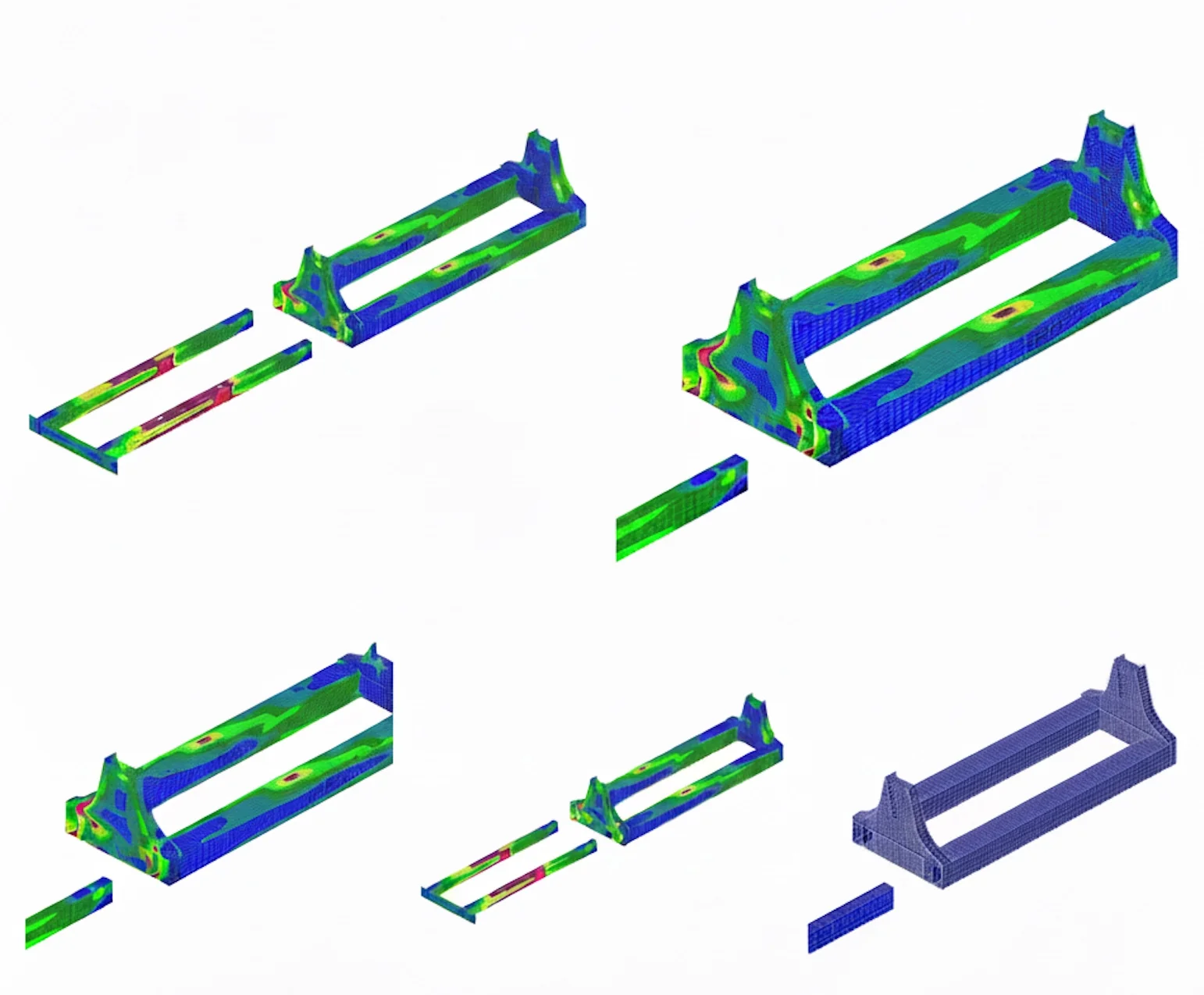

Earls Spreader Model 807 RE Mainframe Weldment

Client: Earls Industries

Location: Greater Vancouver Area, BC

Structural capacity review and finite element analysis supporting fabrication decisions for a 42LT rated load.

Project Overview

This project required an engineering validation of a container spreader mainframe weldment intended for heavy-lift service. The objective was to confirm structural adequacy under a 42LT rated load while providing practical guidance for fabrication and QA/QC.

IFEL built a traceable analysis package that connected load assumptions, material selection, and acceptance criteria to the stress and deformation results produced by the model.

- Finite element analysis with plate-element modeling

- Factored load combinations aligned to applicable standards

- Clear reporting suitable for client documentation packages

Engineering Approach

We modeled primary components using appropriate element types to capture stress distribution in thick-plate regions and welded details. The finite element model utilized plate elements to represent the complex geometry, including thick-plate sections and critical welded connections.

Von Mises stress analysis was performed to evaluate material utilization under factored loading conditions. Results were reviewed for structural integrity and presented with practical recommendations to support decision-making without slowing fabrication.

Outcome

The client received an engineering report confirming structural integrity for the rated capacity. The analysis validated that the mainframe weldment design was adequate for the 42LT rated load, providing confidence for both fabrication and operational use.

Vibration Problem-Solving - Digested Sludge Feed Piping System

LONA Wastewater Treatment Plant

Rapid problem-solving engineering to resolve severe commissioning vibration in a critical sludge feed piping system.

Comox Valley Plant Fire Water System

Vancouver Island, BC

Engineering and design of a firewater system, including hydraulic calculations and constructable alternatives to protect schedule and budget.

BC Hydro UPS & Diesel Genset Enclosure Structural Design

Langley Twp., BC

Structural FEA, detailed design, and full integrity analysis of UPS enclosure and Diesel Genset package enclosure, including seismic and lift design per IEEE 693-2018 and BC Hydro requirements.

Ready to Work With Us?

Want a similar outcome on your project? Tell us your scope and constraints and we’ll propose a clear engineering plan.